- Technical Principles -

18.Jun.2024

Hot Disk 5G Hot Business Opportunity: Challenges by Cooling Technology

The year 2020 marks the large-scale commercialization of 5G technology. With the realization of the Internet of Everything, this ranges from the rise of platform technologies such as the Internet of Things (IoT) and the Internet of Vehicles (IoV) to the extensive application of mobile multimedia and the ubiquity of mobile phones. Major mobile phone manufacturers have successively launched multiple 5G phones. The development of 5G technology is undoubtedly one of the most globally focused key technologies at present. Not only has the research and development of B5G (Beyond 5G) begun, but the focus is also on stable speed, low latency , and the accompanying issues of low power consumption and heat dissipation.

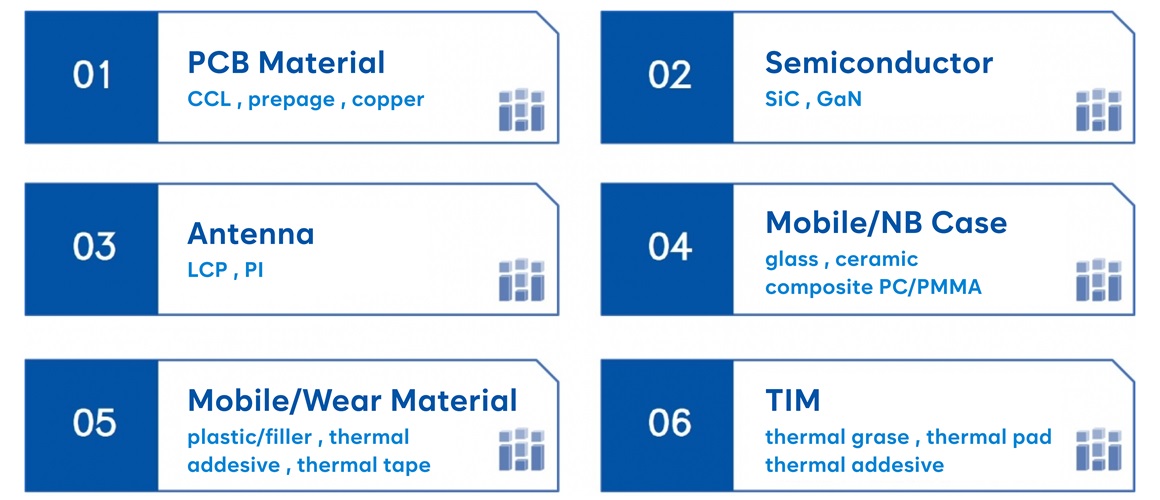

The growth of wireless communication technology has led to an increase in power consumption, raising the requirements for modularization and system integration, with the most direct impact being on module heat dissipation. In terms of heat dissipation methods, passive cooling via natural convection is primarily used for base stations and terminal devices like mobile phones. Below is a summary of the classification of PCB and thermal materials that play a critical role in 5G technology:

The growth of wireless communication technology has led to an increase in power consumption, raising the requirements for modularization and system integration, with the most direct impact being on module heat dissipation. In terms of heat dissipation methods, passive cooling via natural convection is primarily used for base stations and terminal devices like mobile phones. Below is a summary of the classification of PCB and thermal materials that play a critical role in 5G technology:

▲5G related key materials

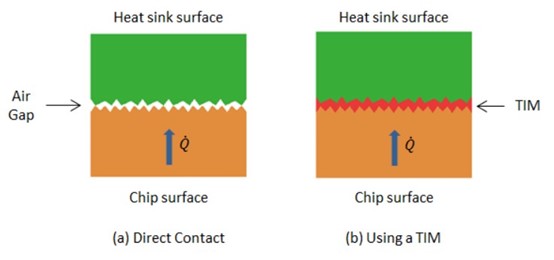

▲Function and schematic diagram of TIM thermal interface material

|

|

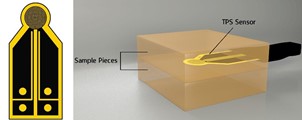

| ▲The left side is a schematic diagram of the Hot Disk TPS3500, and the right side is a schematic diagram of the placement of the Sensor and samples during the Hot Disk test. | |

The main heat dissipation method in a modular system is heat conduction, so the heat dissipation material must have high thermal conductivity. Heat dissipation materials used in computers and mobile phones must also consider surface temperature limitations, so anisotropic heat conduction and heat diffusion characteristics are even more important. At present, the heat dissipation materials mainly used in computers and mobile phones are mainly copper foil and graphite sheets. Another important heat dissipation component is TIM thermal interface material, which includes heat dissipation paste, heat dissipation glue, heat sink fins and other materials. The main function of TIM is to fill the gaps and holes in the solid surface generated when the two materials are joined, reducing the loss of heat transfer. The impact of contact thermal resistance is especially important for passive heat dissipation. Please refer to the schematic diagram below:

The 5G, B5G, 6G technologies puts forward new performance requirements for materials, including PCB materials, semiconductor materials, mobile phone antenna materials, mobile phone shell materials, electromagnetic shielding materials, thermal conductive and heat dissipation materials, etc., which will all usher in changes in 5G applications. Faced with various forms of heat dissipation materials, traditional heat conduction measurement technology also faces challenges. As one of the most reliable thermal conductivity testing methods in the world, Hot Disk complies with the ISO22007-2.2 standard testing specifications and is a testing method of the TPS Transient Plane Source method. The thermal conductivity, thermal diffusivity and specific heat capacity of most material types can be quickly obtained through one-time measurement. It can measure various types of samples such as blocks, liquids, powders, pastes, films, and high thermal conductivity sheets. Hot Disk provide more diverse test modules, such as: anisotropic module (Anisotropic property), thin film module (Thin film), specific heat test module (Specific heat) and low-density high-insulation test module ( Low Density/High Insulator) etc. We also firmly believe that advanced measurement technology like Hot Disk will definitely ride on the wave of 5G technology development and provide industry leaders with the best solutions for all thermal testing needs.

The 5G, B5G, 6G technologies puts forward new performance requirements for materials, including PCB materials, semiconductor materials, mobile phone antenna materials, mobile phone shell materials, electromagnetic shielding materials, thermal conductive and heat dissipation materials, etc., which will all usher in changes in 5G applications. Faced with various forms of heat dissipation materials, traditional heat conduction measurement technology also faces challenges. As one of the most reliable thermal conductivity testing methods in the world, Hot Disk complies with the ISO22007-2.2 standard testing specifications and is a testing method of the TPS Transient Plane Source method. The thermal conductivity, thermal diffusivity and specific heat capacity of most material types can be quickly obtained through one-time measurement. It can measure various types of samples such as blocks, liquids, powders, pastes, films, and high thermal conductivity sheets. Hot Disk provide more diverse test modules, such as: anisotropic module (Anisotropic property), thin film module (Thin film), specific heat test module (Specific heat) and low-density high-insulation test module ( Low Density/High Insulator) etc. We also firmly believe that advanced measurement technology like Hot Disk will definitely ride on the wave of 5G technology development and provide industry leaders with the best solutions for all thermal testing needs.