- Technical Principles -

19.Jun.2024

Hot Disk Introduction and Application of Liquid Metal

Introduction

Liquid Metal is a low-melting-point alloy that remains in a liquid state at room temperature. It possesses excellent thermal and electrical conductivity, is stable, non-volatile, safe, and non-toxic. In recent years, the rapid development of high-efficiency chips has brought about significant challenges related to waste heat. If this waste heat is not effectively dissipated, it can cause chips to overheat and short circuit. The contact surface between the chip and the heat sink is often imperfect, which is why thermal interface materials, commonly known as thermal paste, are applied.

The primary focus of replacing silicon-based thermal paste with Liquid Metal is its thermal conductivity and gap-filling capability. Compared to thermal paste, Liquid Metal significantly enhances thermal conductivity. Therefore, research units developing Liquid Metal prioritize the measurement of its thermal conductivity for different compositions. In Taiwan's electronics industry, the three most commonly used methods for measuring thermal conductivity are Hot Disk-ISO22007-2.2, Laser-ASTM-E1461 and Steady-State Method-ASTM D5470. Each method has its strengths in testing thermal pastes, metallic thermal materials, and ceramic thermal materials. The Hot Disk-ISO22007-2.2 method is the most widely applicable, Laser-ASTM-E1461 emphasizes high-temperature testing, and ASTM D5470 has numerous traditional applications. However, for measuring Liquid Metal, Hot Disk offers advantages such as requiring small sample sizes, high accuracy, and precision, and simultaneously providing thermal conductivity and thermal diffusivity data. Below is a description of the Hot Disk testing method.

The primary focus of replacing silicon-based thermal paste with Liquid Metal is its thermal conductivity and gap-filling capability. Compared to thermal paste, Liquid Metal significantly enhances thermal conductivity. Therefore, research units developing Liquid Metal prioritize the measurement of its thermal conductivity for different compositions. In Taiwan's electronics industry, the three most commonly used methods for measuring thermal conductivity are Hot Disk-ISO22007-2.2, Laser-ASTM-E1461 and Steady-State Method-ASTM D5470. Each method has its strengths in testing thermal pastes, metallic thermal materials, and ceramic thermal materials. The Hot Disk-ISO22007-2.2 method is the most widely applicable, Laser-ASTM-E1461 emphasizes high-temperature testing, and ASTM D5470 has numerous traditional applications. However, for measuring Liquid Metal, Hot Disk offers advantages such as requiring small sample sizes, high accuracy, and precision, and simultaneously providing thermal conductivity and thermal diffusivity data. Below is a description of the Hot Disk testing method.

Hot Disk Testing Method

TechMax Technical Co., Ltd provides the Hot Disk method for measuring the thermal conductivity of Liquid Metal. The Hot Disk can use different modules to handle various material types, including solids, liquids, powders, pastes, films, low-insulation materials, high thermal conductivity materials, and anisotropic thermal materials. As long as there is a sufficient quantity of Liquid Metal (approximately 100ml-150ml), the Hot Disk can be used for testing.

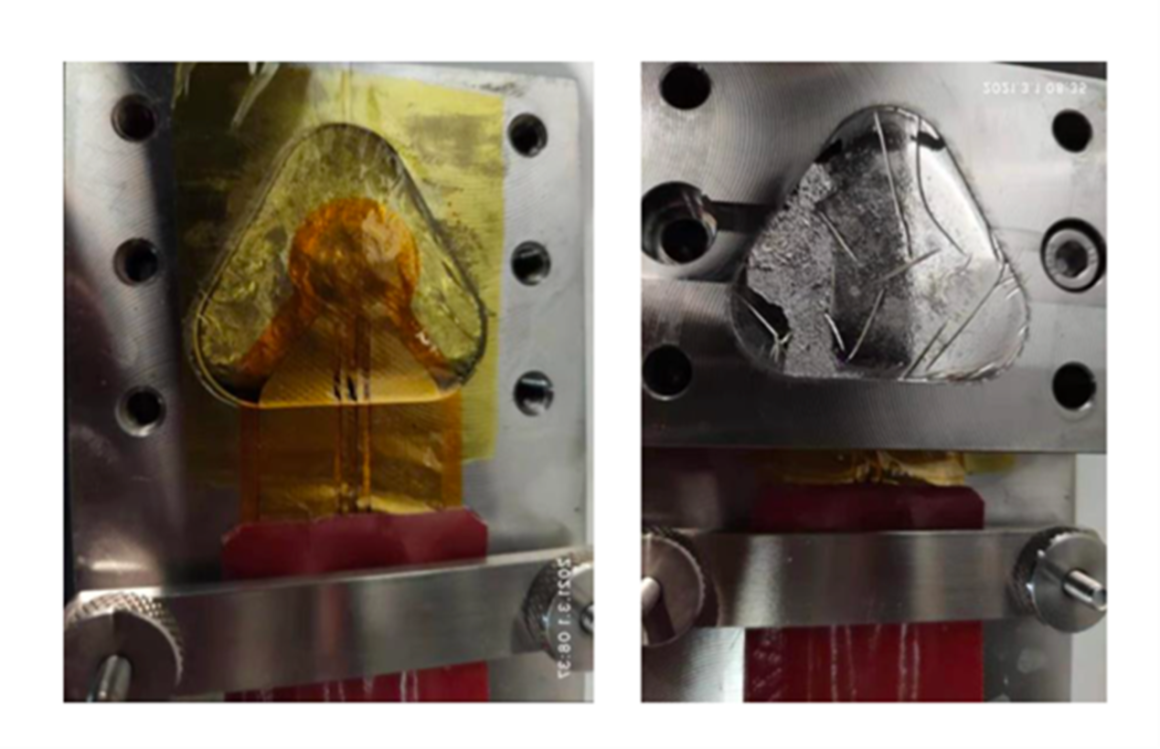

However, due to the high cost of Liquid Metal, obtaining 100ml-150ml at once can be quite expensive. Therefore, the Hot Disk also has a corresponding Phase Change Material (PCM) holder that reduces the sample amount needed for testing to approximately 30ml. Figure 1 illustrates the use of the PCM holder for testing Liquid Metal.

However, due to the high cost of Liquid Metal, obtaining 100ml-150ml at once can be quite expensive. Therefore, the Hot Disk also has a corresponding Phase Change Material (PCM) holder that reduces the sample amount needed for testing to approximately 30ml. Figure 1 illustrates the use of the PCM holder for testing Liquid Metal.

|

|

| ▲The Clamp for Liquid Metalthermal conductivity measurement | ▲Hot Disk TPS 3500 |

Thermal Simulation Methods

In addition to measuring the intrinsic thermal conductivity of Liquid Metal, various thermal simulation methods are necessary to evaluate the thermal performance of actual samples. These methods help measure thermal conductivity, thermal diffusivity, and specific heat.

Hot Disk provides various modes that offer comprehensive information suitable for different products and applications, including thermal conductivity and thermal diffusivity in different directions (X-Y, Z) and specific heat (Cp). This makes it highly suitable for testing thermal interface materials.

Hot Disk provides various modes that offer comprehensive information suitable for different products and applications, including thermal conductivity and thermal diffusivity in different directions (X-Y, Z) and specific heat (Cp). This makes it highly suitable for testing thermal interface materials.