- Technical Information -

20.Jun.2024

Hot Disk Thermal Conductivity Measurement of Ceramic Substrates SiC, Al₂O₃, AlN

Recently, ceramic cooling substrates made of silicon carbide (SiC), aluminum oxide (Al2O3), and aluminum nitride (AlN) have been widely used in thermal engineering solutions. As technology advances and products become smaller, lighter, and more functional, severe heat accumulation issues arise. To address these issues, thin and insulated high thermal conductivity cooling sheets are increasingly applied. Regardless of the type of cooling sheet, it is necessary to test the thermal conductivity (TC) and the coefficient of thermal expansion (CTE) under heat-resistant characteristics. TechMax Technical Co., Ltd has extensive experience in both research and development as well as quality management, providing customers with comprehensive testing methods.

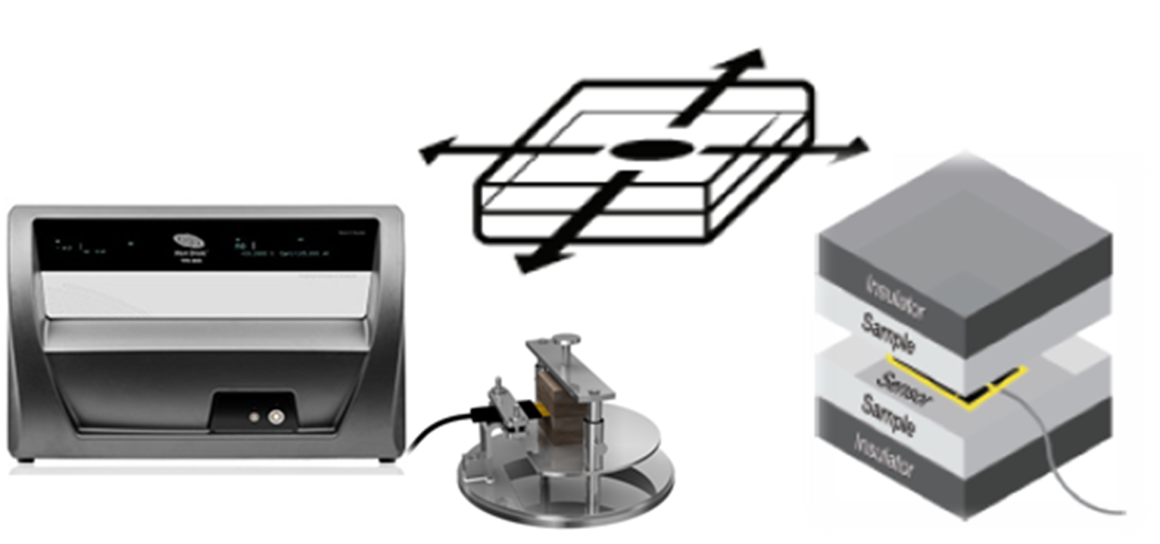

Most of manufacturers believe that the CTE of aluminum nitride (AlN) ranges from 4 to 5 ppm, with a thermal conductivity of 160 to 200 W/mK. However, some Japanese manufacturers or those with high production capabilities often face issues where substandard manufacturing processes result in products with internal pores, cracks, high CTE, or low TC, sometimes only reaching 130 W/mK. Therefore, using a Thermomechanical Analyzer (TMA) to test CTE and Hot Disk TPS 2500S or TPS 3500 to measure Thermal Conductivity (TC) are crucial factors in monitoring the quality characteristics of AlN materials. Substrate materials are also commonly used in various composite or multilayer materials. If the CTE does not match, the product is likely to warp or crack.

Most of manufacturers believe that the CTE of aluminum nitride (AlN) ranges from 4 to 5 ppm, with a thermal conductivity of 160 to 200 W/mK. However, some Japanese manufacturers or those with high production capabilities often face issues where substandard manufacturing processes result in products with internal pores, cracks, high CTE, or low TC, sometimes only reaching 130 W/mK. Therefore, using a Thermomechanical Analyzer (TMA) to test CTE and Hot Disk TPS 2500S or TPS 3500 to measure Thermal Conductivity (TC) are crucial factors in monitoring the quality characteristics of AlN materials. Substrate materials are also commonly used in various composite or multilayer materials. If the CTE does not match, the product is likely to warp or crack.

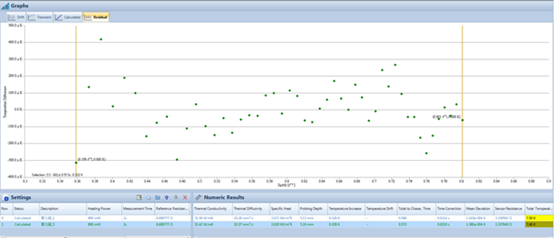

▲Thermal Conductivity Test Results of Al2O3 Aluminum Oxide

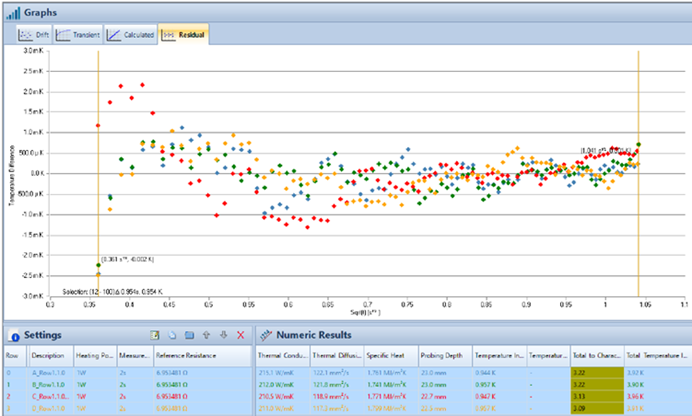

▲Test Results of Aluminum Nitride AlN Substrates

▲Comparative Test Results of Aluminum Nitride AlN Substrates with Different Formulations

Regardless of the raw materials used in the production of ceramic substrates, precise TC values can be tested: aluminum oxide at 31.59 W/mK, aluminum nitride at 166.6 W/mK, and aluminum nitride with different formulations at 210.5 W/mK. In the tests shown in Figure 2, Hot Disk tested under three different power conditions, showing very stable results. Figure 3 demonstrates whether formulation differences can be detected under the same production process, with significant discernible improvements from 210.5 W/mK to 215.1 W/mK.

The tests of thermal expansion coefficient (CTE) or thermal conductivity (TC) under general conditions clearly reveal product quality and manufacturing capabilities. Hot Disk method corresponding to ISO-22007-2.2 is non-destructive, allowing the sample to be reused after testing. Its extremely short testing time provides immediate solutions for R&D and quality control.

The tests of thermal expansion coefficient (CTE) or thermal conductivity (TC) under general conditions clearly reveal product quality and manufacturing capabilities. Hot Disk method corresponding to ISO-22007-2.2 is non-destructive, allowing the sample to be reused after testing. Its extremely short testing time provides immediate solutions for R&D and quality control.

▲Hot Disk TPS3500 Schematic and Slab Method for ceramic Slab